Applus+ RA, leading China’s EV component tests, one investment at a time

时间:2023-01-18 浏览数量:3715

Safeguarding the highest safety and quality standards in China’s high-paced electric vehicle (EV) industry, Applus+ Laboratories has climbed to the top as a trusted testing specialist for EV manufacturers and other players in the supply chain.

What does it take to guarantee quality and safety throughout China’s hasty EV growth? An ongoing investment in facilities, capabilities, and solid accreditations in the automobile industry, and that’s exactly what our Applus+ RA team is bringing to the table today.

NOURISHING SAFETY AND QUALITY IN CHINA’S RAPID EV GROWING INDUSTRY

Thanks to its electric and electronic know-how, government incentives, and its ambitious goal to lead the EV race, China’s EV industry is growing at a hefty pace. According to CPCA (China Passanger Car Association), the penetration rate of new energy vehicles (NEVs) in 2022 lies above 25% of the total market sales, with more than 6.5 M units sold annually. In China, NEVs include plug-in hybrid, pure electric, and fuel cell vehicles, meaning, vehicles that use new power systems and that are driven by new energy sources.

As manufacturers aim to meet high volumes of demand and speed up the manufacturing process, providing an efficient testing service has never been more important. Especially incorporating technological breakthroughs, such as faster charging times and other electrical and electronic assets and gadgets inside the EV.

All of the EV components, including the battery pack, charging system, motor, auxiliary systems have their own design and component parts that require individual and cohesive testing for design verification, product validation and compliance. Our lab capabilities, can help OEMs and its tiers meet their requirements in:

AUTOMOTIVE ELECTRONICS AND BATTERIES TESTING

- Electronic Power Drive Testing: EMC testing of EVmotors with mechanical load.

- Battery Testing: EMC testing

- High Voltage Components Testing: Expertise in HV systems testing, covering EMC, Electrical, Environmental and Vibrations.

- Low Voltage Components Testing: Complete Validation plans for LV components

- Comprehensive Testing for LV/HV Harness: Expertise in terminals, connectors, cables and harness assemblies.

AUTOMOTIVE STRUCTURES, COMPONENTS, AND MATERIALS TESTING

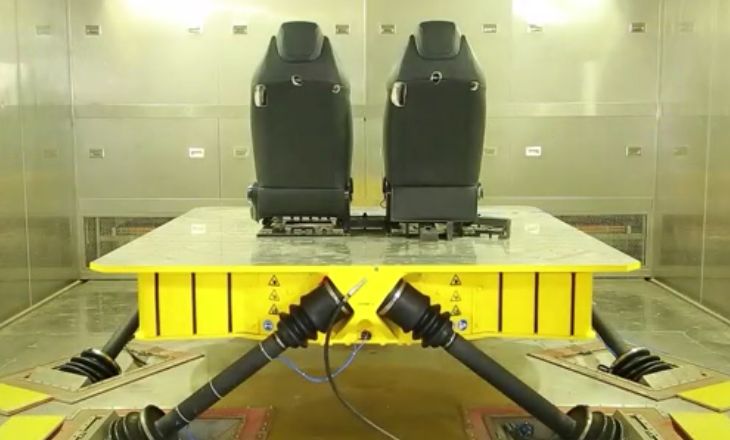

- Mechanical Strength and Operational Stability: End-to-end testing, from test conceptualization to product development and approval. Operation Loads simulation and fatigue tests on all vehicle components.

- Environmental Durability: Vibrations, climatic, and mechanical loads on components. Weathering, salt spray, IP-protection, and solar simulation tests.

- Materials Testing: Materials characterization and quality assurance on composites, metals, polymers, electro-plated parts, leather, textiles and coatings.

- Acoustics & BSR: Anechoic chambers equipped with shakers to detect Buzz, Squeak and Rattle (BSR) issues.

BACKING UP EV TECHNOLOGICAL BREAKTHROUGHS AS EMC TESTING LEADERS

Electromagnetic compatibility (EMC) tests have a new-found importance for OEMs, and this is where our Applus+ RA experts thrive. Our capabilities ensure that EMC requirements can be tested, independently of the preferred method for each OEM.

Our recently acquired reverberation chamber allows for a more comprehensive EMC performance analysis fit for higher voltage and frequency trends. A growing need due to technological improvements like faster battery charging times and improved connectivity.

We also count with nine of our semi-anechoic chambers, fit to test key components such as electronic motor control, converters, and on-board chargers (OBC).

EXPERTS IN CONNECTOR AND HARNESS TESTING IN HIGH-VOLTAGE TRENDS

Another growing tendency in the EV manufacturing industry are the number of wires and connectors inside the vehicle, combine this with higher voltage levels for faster charging times, and you’ve a recipe for potential risks.

Our connector and harness testing labs work to test there are no potential hazards due to battery overheating interfering with wiring. We offer OEMs environmental, aging, mechanical, electrical, functional endurance, shielding efficiency, signal integrity and protection testing.

WHAT'S NEXT?

Even if we’ve come a long way testing in the field of raw materials, traditional electronic and electrical parts, and high voltage components, our Applus+ RA experts know the possibilities for this growing market are endless.

Want to get more in-depth information about our services and progress in the field? Check out our official Applus+ RA site or get in touch with one of our specialists.